Rigid Box Materials Explained: Greyboard, Paper Wraps, and Specialty Papers

Rigid boxes are known for their solid structure, refined appearance, and long-lasting performance. While visual design often attracts attention, the real quality of a rigid box is determined by the materials used in its construction. For brands and importers sourcing custom rigid box packaging, understanding material choices is essential for balancing durability, cost, aesthetics, and sustainability. This article explains the key materials used in rigid box packaging, focusing on greyboard, paper wraps, and specialty papers, and how each contributes to the final product.

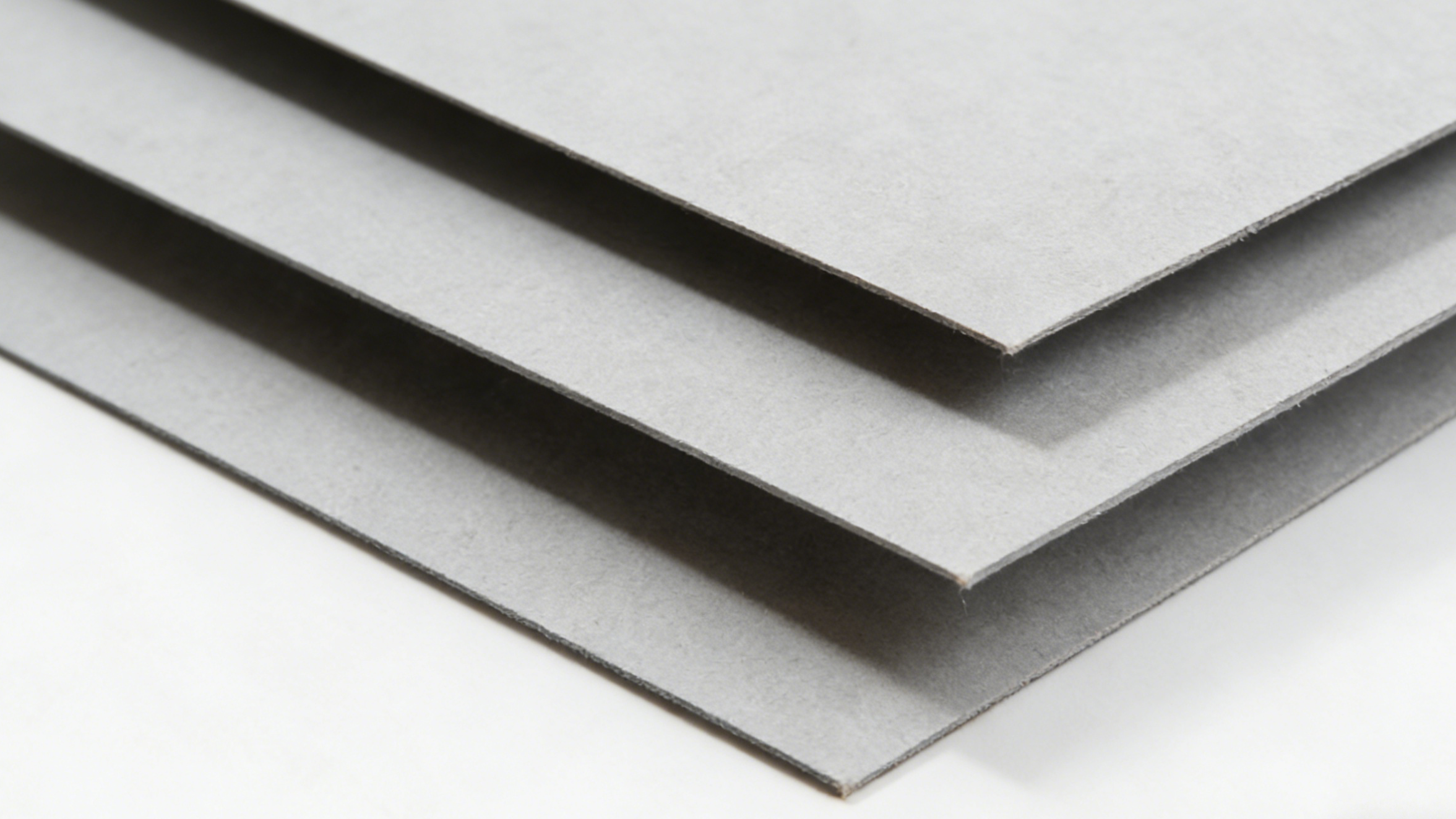

Greyboard: The Foundation of Structural Strength

Greyboard is the core material that gives rigid boxes their strength and shape. Unlike folding cartons, rigid boxes are built from thick, compressed paperboard that does not bend easily. This material is typically manufactured from recycled paper fibers, making it both durable and widely accepted as an environmentally responsible option.

The strength of a rigid box largely depends on the thickness and density of the greyboard. Common thickness options range from approximately 800gsm to over 1800gsm. Thicker greyboard provides greater resistance to pressure and deformation, which is why rigid boxes are often used for premium products that require strong protection during storage and transportation.

Greyboard also supports a wide variety of rigid box structures. Whether used in lift-off lid boxes, magnetic closure boxes, drawer-style boxes, or collapsible rigid boxes, greyboard ensures the packaging maintains its shape over time. Choosing the correct greyboard specification is a critical step in custom rigid box production, as it directly affects both performance and perceived quality.

Paper Wraps: Shaping the Visual Identity

Paper wraps are applied to cover the greyboard structure and define the exterior and interior appearance of a rigid box. While greyboard provides strength, paper wraps deliver branding, texture, and color. Without proper wrapping, even the strongest box

would lack visual appeal.

Common paper wrap options include coated paper, uncoated paper, kraft paper, and textured paper. Coated paper is often selected for packaging that requires sharp printing details and vibrant colors. Uncoated and kraft papers create a more natural and understated look, which is popular among brands focused on simplicity or sustainability.

Paper wraps also serve as the base layer for surface finishes such as hot foil stamping, embossing, debossing, spot UV, and lamination. The type of paper used directly influences how these finishes appear and perform. Smooth paper supports precise printing and foil application, while textured paper adds depth and tactile contrast.

Proper wrapping techniques are essential to achieve clean edges, smooth corners, and strong adhesion. High-quality paper wrapping enhances both durability and visual consistency across bulk custom rigid box orders.

Specialty Papers: Enhancing Premium Appeal

Specialty papers are used when rigid box packaging needs to convey a higher level of sophistication or uniqueness. These materials include linen paper, soft-touch paper, metallic paper, black-core paper, and custom-patterned paper. Specialty papers are chosen not only for appearance, but also for how they feel when handled.

Luxury and high-end brands often rely on specialty papers to create a memorable unboxing experience. Soft-touch paper offers a smooth, velvet-like surface that suggests refinement, while metallic paper introduces subtle shine without overwhelming the design. Black core paper is commonly used in premium rigid boxes because it maintains a consistent color at cut edges, enhancing overall craftsmanship.

Although specialty papers increase material costs, they significantly raise perceived product value. For brands competing in premium markets, this added value often justifies the investment.

Cost and Sustainability Considerations

Material selection has a direct impact on rigid box pricing. Greyboard thickness, paper type, and specialty materials all influence production cost. Thicker boards and premium papers require more material and processing time, while standard options help manage budgets for large-volume orders.

From a sustainability perspective, rigid box materials offer flexibility. Most greyboard is made from recycled content, and many paper wraps are recyclable or certified by recognized forestry standards. Brands seeking eco-friendly custom rigid box solutions can reduce environmental impact by choosing recyclable papers, minimizing plastic-based laminations, and optimizing material usage.

Balancing strength, appearance, cost, and sustainability is essential when selecting rigid box materials. Careful material planning ensures packaging meets both functional requirements and market expectations.

Conclusion

Rigid box packaging relies on the combined performance of multiple materials. Greyboard provides the structural backbone, paper wraps define branding and appearance, and specialty papers elevate the packaging experience. Understanding these materials allows buyers to make informed decisions when developing custom rigid box packaging. With the right material choices, rigid boxes can deliver durability, visual impact, and long-term brand value.