Rigid Boxes vs Magnetic Boxes: Key Differences You Should Know

Rigid boxes have become a cornerstone of premium packaging across industries such as cosmetics, electronics, fashion, and luxury gifts. Within this category, magnetic boxes are often mentioned alongside traditional rigid boxes, which can confuse brands choosing the right packaging solution. Although magnetic boxes are a type of rigid box, the structural differences, user experience, and cost implications between standard rigid boxes and magnetic boxes are significant. Understanding these differences is essential when selecting packaging that aligns with product needs and brand positioning.

Rigid boxes are typically constructed from thick paperboard, offering strong structural integrity and a premium feel. They are widely valued for their durability and versatility, making them suitable for both retail display and shipping protection. Traditional rigid boxes come in several common structures, such as lift-off lid boxes, drawer-style boxes, and book-style boxes without magnetic closures. These structures focus on simplicity, strength, and cost efficiency while still delivering a high-end appearance.

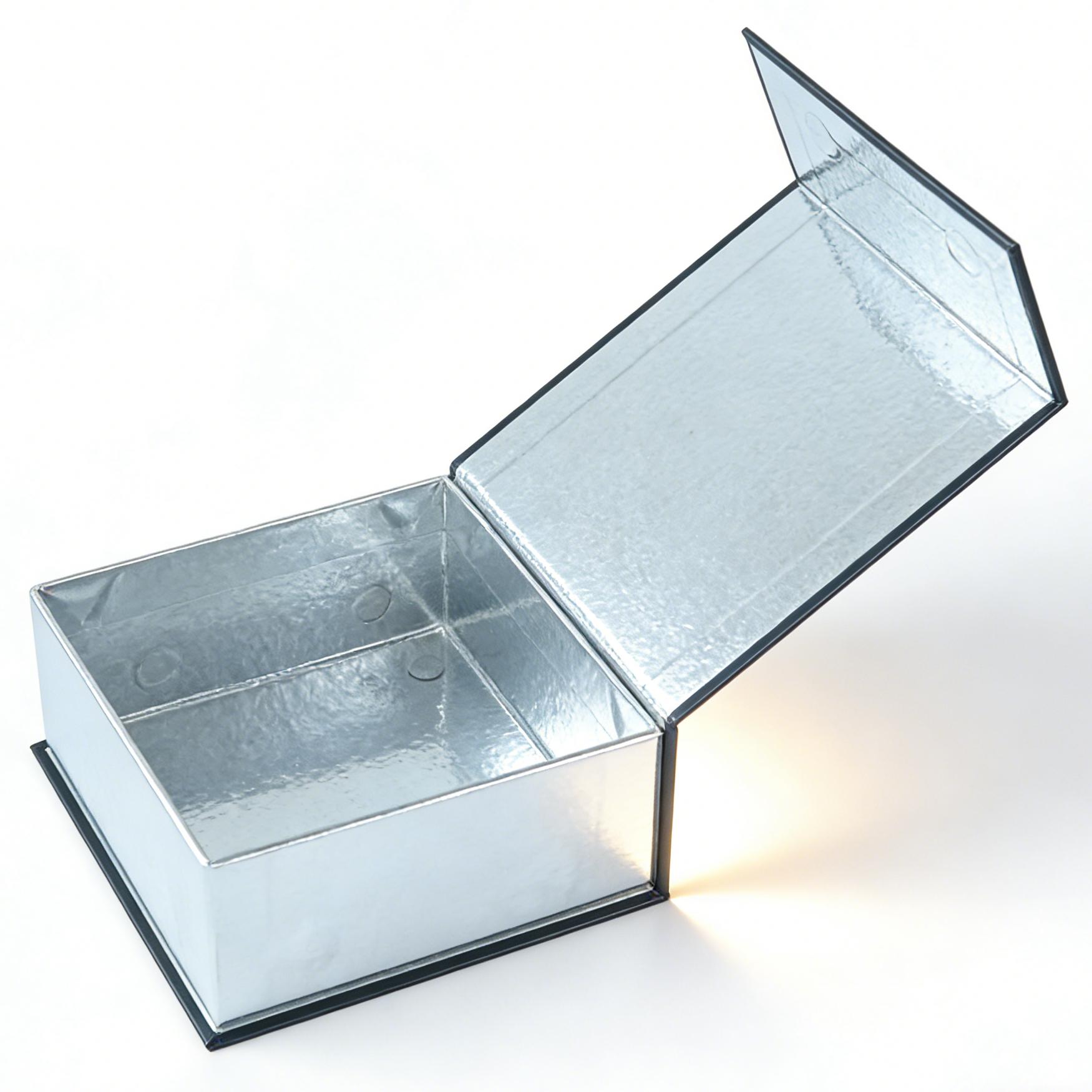

Magnetic boxes, on the other hand, are a specialized form of rigid box that incorporates embedded magnets into the lid and front panel. This design allows the box to open and close smoothly with a subtle snap, enhancing the overall unboxing experience. Magnetic boxes are often associated with luxury branding because they feel more interactive and refined. The presence of magnets also improves reusability, as the box maintains its shape and closure after repeated use.

One of the key differences between rigid boxes and magnetic boxes lies in user experience. Traditional rigid boxes usually rely on friction-fit lids or sliding mechanisms. While these designs are reliable and elegant, they tend to be more straightforward. Magnetic boxes introduce an element of ceremony to the unboxing process. The controlled opening motion and secure closure create a sense of quality that appeals to high-end consumers, particularly in gift packaging and premium product launches.

Cost is another important factor when comparing these two packaging options. Standard rigid boxes generally have lower production costs due to simpler structures and fewer components. They are often preferred for large-volume orders where budget efficiency is a priority. Magnetic boxes involve additional materials, including magnets and more complex assembly processes, which increase unit costs. For brands with premium pricing strategies, this higher cost is often justified by the added perceived value.

Customization potential also differs slightly between rigid boxes and magnetic boxes. Both options support extensive customization in terms of size, shape, printing, and surface finishes such as foil stamping, embossing, debossing, and soft-touch lamination. However, magnetic boxes provide more design opportunities for internal layouts and opening mechanisms, which can enhance storytelling and brand presentation. Traditional rigid boxes excel in minimalistic designs that emphasize materials and craftsmanship.

From a practical standpoint, shipping and storage considerations can influence the choice. Standard rigid boxes are often easier to stack and may require less manual assembly, depending on the structure. Magnetic boxes typically require careful handling during production and transportation to maintain alignment and closure performance. These factors can affect logistics efficiency, especially for international shipping.

Sustainability is becoming an increasingly important consideration for rigid packaging. Traditional rigid boxes made entirely from paper-based materials are generally easier to recycle. Magnetic boxes may include non-paper components, which can complicate recycling unless designed thoughtfully. Brands focused on sustainability should evaluate material choices, magnet placement, and end-of-life disposal when selecting magnetic rigid boxes.

In summary, rigid boxes and magnetic boxes serve different purposes within premium packaging. Standard rigid boxes offer strength, versatility, and cost efficiency, making them suitable for a wide range of products and volumes. Magnetic boxes elevate the unboxing experience and reinforce luxury positioning, often at a higher cost. Choosing between the two depends on brand goals, budget, product value, and desired customer experience. Understanding these key differences helps businesses make informed packaging decisions that support both functionality and brand image.